Hello Guest,

How do you stop contamination entering high hygiene environments?

The low down on contamination

80%

27%

215K

80% of contamination enters

critical environments via feet or wheels

Only 27% of contamination is

prevented by peel-off mats

215,000 particles released every time a tacky

mat is peeled

Contamination is a major and growing concern in cleanrooms, critical areas and controlled environments, from facilities for pharmaceutical, automotive and semiconductor manufacturing to food processing units and data storage centres. Although contamination from foot, wheel and airborne particles is often dismissed as simply ‘dust’ or ‘dirt’, the dangers it poses can be devastating. Contamination in a critical environment can have a major impact on quality, product yield, effectiveness and profitability.

Particles

The visible and invisible enemy

Particulate contaminants in critical areas are known to adversely affect quality, product yield, operational effectiveness and profitability. Particles can be viable or non-viable, made from different materials, come from the different places and travel large distances.

Particles outside the critical area can also be a potential problem, especially the small, light, invisible particles. Even fairly large particles that have settled on the floor are easily crushed into very small particles and redistributed back into the air. These airborne particles then get transferred into the critical area where they present a potential hazard. There are two main types of particle contamination:

External – Gross atmospheric contamination, which infiltrates your facility.

Internal – Humans can generate 5-10 million skin, hair and dirt, and clothing particles every minute.

Key properties of fine particles:

They move with the air in which they are suspended.

Due to gravity they settle out of the air slowly and can remain airborne for long periods of time.

As they settle, they risk contacting and contaminating critical products and processes.

The small, light, particles (<5um) normally invisible to the naked eye are commonly called Airborne Molecular Contaminates (AMCs) or Ultra Fine Particles (UFP’s). They can become suspended for hours it the surrounding environment where they spread quickly, polluting the atmosphere.

Unseen airborne allergens such as pollen, mould spores and dust mites, which float in the air and are inhaled. Pollen has been found 400 miles out to see and two miles up in the air.

A 1-micron particle may take as long as 15 hours to settle without movement. Whether the environment in which you operate is industrial, controlled, critical or sterile, Dycem contamination controls mats and flooring are proven to reduce particle counts by up to 99%.

Here’s how to win the war against contamination

The Technology

• Dycem manufactures a technically sound and proven contamination control solution. Impregnated with Biomaster antimicrobial technology and manufactured to an optically smooth finish.

• Dycem’s polymeric mats and flooring can capture and retain up to 99.9% of both foot and wheel-borne contamination and up to 75% of airborne contamination. In addition, the product’s antimicrobial properties help inhibit the growth of over 20 organisms on contact, including E.Coli, Salmonella, Listeria, plus many more.

Size

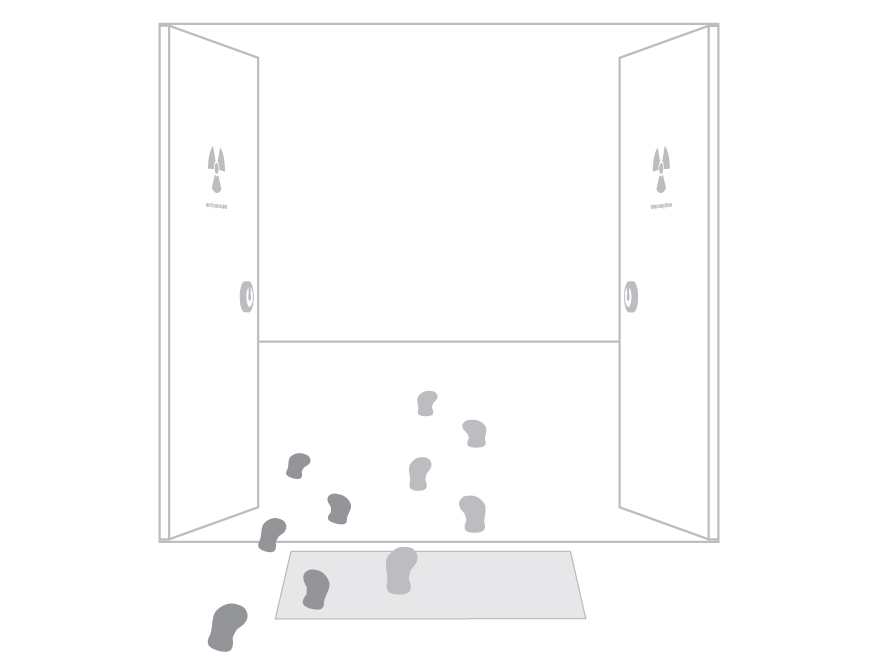

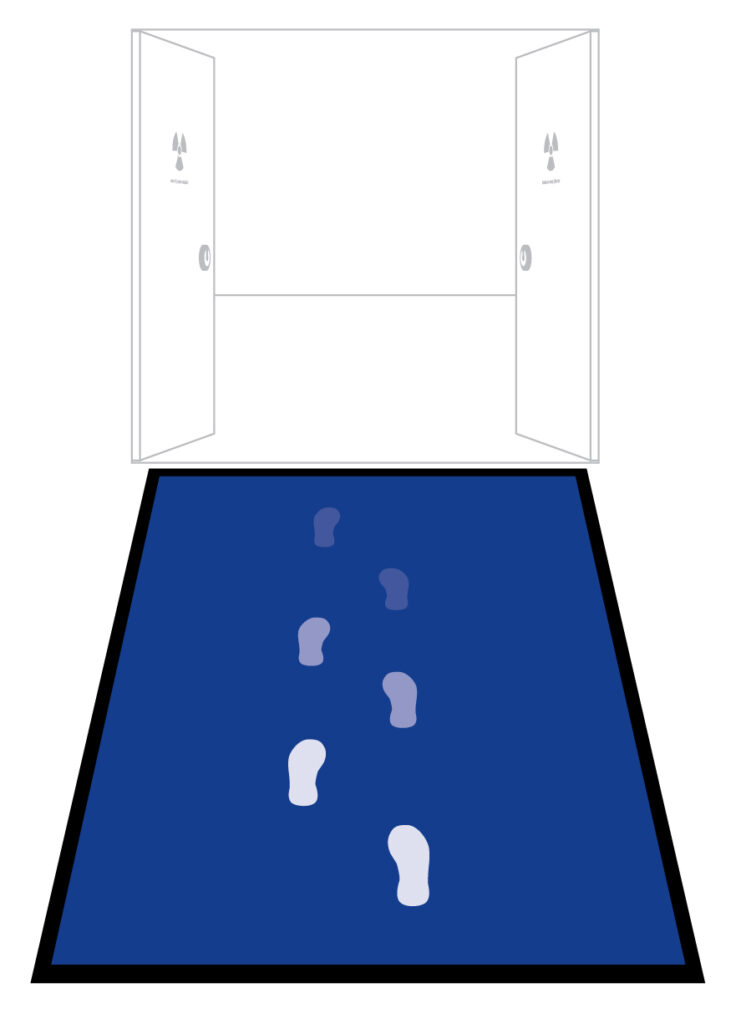

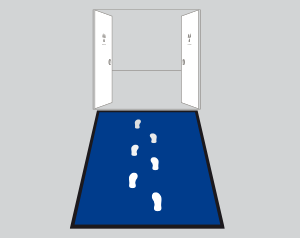

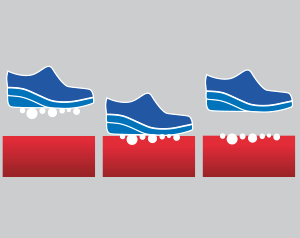

It is well accepted that to effectively remove contamination from feet and wheels, it takes a total of six footfalls or three full wheel rotations. Only Dycem delivers this.

Suppleness

Dycem’s unique polymeric surface is soft and supple, conforming to shoe and wheel profiles and collecting particles between 0.1 and >100 microns.

Smoothness

Dycem’s exceptionally smooth surface creates a natural tack and a high degree of short-range electromagnetic forces (Van der Waals). This enables it to attract, collect and retain up to 99.9% of foot and wheel-borne contamination, as well as up to 75% of airborne particles.

Silver

Dycem products all include Biomaster – a silver ion-based anti-microbial, proven to provide effective and lasting protection on more than 50 different organisms, including Salmonella, E.coli, Listeria and MRSA.

Static Dissipative

Both Cleanzone and Workzone products have a surface resistivity of 108 ohm, allowing it to help reduce Electrostatic Discharge (ESD) and the damage it can cause.

Service

Dycem offers complete customer support before, during, and after your purchase. As part of your Dycem purchase, a yearly particle collection efficiency test (AFG test) will be conducted by a Dycem representative, including a report produced for your records to show current effectiveness of the mats or flooring.

Frequently asked questions

Enter your email address and we’ll send you a link to an interactive tool showing you where you can use it with many installation photos for each use.

Who is Dycem?

Established in 1966, Dycem is a world-leading manufacturer of contamination control mats and flooring. We are a global organisation with headquarters in Bristol, England. We also have offices in Rhode Island, USA, The Woodlands, Texas, Muntinlupa City, Philippines and as well as contamination control specialists on the ground in all major hubs across the world.

What are the benefits of installing Dycem products?

Dycem’s contamination control mats and flooring are scientifically proven to be the most effective, long lasting and high performance method of minimising foot, wheel and airborne contamination.

• Companies across a variety of industries have all experienced a long list of benefits after installing Dycem, including:

• Reduced floor and air particulate counts in controlled or critical areas.

• Improved product yield, cost savings and profitability.

• A visible barrier zone, alerting personnel that they are about to enter a critical area.

• Unavoidable decontamination as Dycem mats or flooring cannot be bypassed when properly sized and positioned at all critical control paths.

• Long-lasting, cost effective solution compared with peel-off mats and other alternatives.

• Only effective solution for wheeled traffic.

• Reduced microbial counts due to Biomaster, a high-performance antimicrobial additive in all Dycem products.

• Reduced carbon footprint as Dycem products are environmentally friendly – creating significantly less waste than peel-off mats or shoe covers and containing no Silicon, latex or DOP outgassing.

• Easy to clean, maintain, and incorporate into existing Standard Operating Procedures (SOP’s).

• Reduced critical area cleaning costs due to less contamination entering the environment.

• Static dissipation prior to ESD sensitive areas.

• Cleaner shoes and wheels give improved ESD contact.

• Improved quality of working life due to reduced allergens in the atmosphere.

• One year warranty.

• A network of global customer support with dedicated local specialists on the ground.

What quality standards do Dycem comply with?

Dycem Quality and Standards

Dycem has always strived to develop high-quality products and services that ensure customer satisfaction is achieved and, wherever possible, exceeded.

Our product range is continually being improved to ensure it meets the changing needs of customers. This commitment to ongoing improvement is complemented by excellent sales and customer service.

In order to achieve these simple but essential goals, the company operates a management system that conforms to the relevant national and international requirements. This system ensures a customer and quality focus exists throughout the organisation, from product development, through manufacturing, to the delivery of our products, and beyond.

Our production processes are continuously monitored to make certain that products meet document requirements and that the products delivered to our customers conform to all relevant standards of the modern market.

The company sets measurable objectives and targets at all levels within the organisation, which are regularly reviewed, to ensure its performance is in line with the top level quality policy and that customer focus remains at the forefront of the agenda at all times. Our systems are also evaluated by both internal audits and by periodic external audits.

Dycem complies with national and international legislation relating to the protection of human health and the environment from the use of chemicals. We strictly monitor our supply chain to ensure chemicals on the list of substances of very high concern are not present in our products. The company also carries out periodic testing of products at independent accredited laboratories.

CYBER ESSENTIALS COMPLIANCE CERTIFICATE

Do you have any scientific data or white papers to back up your claims?

1. The five risks of using peel off mats

2. Effective reduction in the microbial count in Cleanrooms with the use of polymeric mats

3. An evaluation of the effectiveness of polymeric flooring compared with the “peel-off” mats

4. Airborne contamination reduced by 75%

5. Time lapse photography to demonstrate the potential antimicrobial abilities of Dycem flooring

6. The use of polymeric flooring to reduce contamination in a clean room area

7. Controlling and monitoring biosecurity on vivarium floor surfaces

8. Cost of data centre outages

9. Hospital study – A final floor shows for bugs

10. Effectiveness of shoe covers for bio exclusion within an animal facility

11. Dust explosions ATEX study – Relationship between dirtiness and hazardous zones

12. Environmental factors in data centres

13. The nature and environmental impact of control of floor level contamination

14. A major medical device manufacturer reveals significant airborne reduction counts

15. Controlling microbial contamination is essential to medical device performance and reliability

How do Dycem products work with electrostatic discharge?

Electrostatic discharge (ESD) is caused by a number of factors and is commonly generated by the contact of materials. It can be produced by everyday occurrences, such as a person picking up a piece of polystyrene packaging or walking across a carpet; it can even be caused by dust in the environment. Positive and negative charges are stored in materials and carried by people. The human body is capable of storing a charge up to 25,000V. This charge is then dissipated (ESD) through the receiving object as the current seeks an unimpeded path. An object’s metal chassis will often act as the conductor for the static to strike, but it can occur through other materials. Static control is especially critical in the manufacture of electronic assemblies and components such as circuit boards and semi-conductors. As it is almost impossible to avoid static-generating actions the best way to avoid damage to ESD sensitive equipment is to create an environment that inhibits the build-up of static. This can include the exclusion of highly charging materials from the controlled area and using grounding mats, such as Dycem’s contamination control mats or flooring, which are proven to dissipate static at 108 ohm and reduce the damage it can cause.

What is Biomaster and how does it work?

Dycem has an added ingredient – Biomaster, which is incorporated into our contamination control flooring during manufacture. This product contains silver ions, which have naturally occurring antimicrobial properties. Silver has been used for hundreds of years to prevent the growth of bacteria. Having a low toxicity makes Biomaster ideal for all applications. You can put your trust in Dycem knowing that we use this highly effective additive in all our products. As Biomaster is added to Dycem during manufacture, it is not something that can diminish, for example if were applied as a coating instead and provides longer lasting effectiveness against microbial growth. The silver ions within Biomaster bind to the bacterial cell wall, and thus prevent growth by damaging it. The bacteria can no longer grow as their DNA has been damaged and they can no longer replicate. They can no longer produce energy either and therefore die. Silver is inorganic and non-leaching which means, unlike organic antimicrobial technologies it stays within the item it is added to and provides effective and lasting antimicrobial protection without allowing bacteria to develop resistance. Silver ion technology has been independently tested in over 2000 applications and has been proven to reduce the growth of over 50 harmful organisms by up to 99.9%

What chemical can I clean Dycem products with?

What chemical can I clean Dycem products with?

How long do Dycem mats of flooring last?

Dycem products have a life span on average of around 3-5 years and depending on traffic and general usage, a Dycem mat or floor will continue to be effective for longer than 5 years. Over time, the effectiveness of the flooring will diminish, but studies have shown even after several years of use, a well maintained Dycem floor is still twice as effective as a brand-new peel-off mat.

Which Dycem mat or flooring is best for me?

- Dycem has a range of product types and installation methods that can be combined to suit the unique needs of our customers.

- Our CleanZone product range is designed for pedestrian traffic and light carts.

- Our WorkZone product range is designed for the rigors of heavy wheeled traffic such as forklifts and pallet jacks.

- Request a site survey from our team of Dycem contamination control specialists to help you decide which product will work best for you. After a site survey at your facility, the specialist can make recommendations to ensure you get the right type of control in your cleanrooms and controlled environments at the best value.

How much does Dycem cost?

- The majority of our customers find Dycem to be an extremely cost-effective way to eliminate dust and dirt particles from entering their cleanroom or controlled environment. Dycem has helped companies save money by reducing consumables spending and waste disposal costs, improving product yields and by lowering cleaning and maintenance costs.

- After a site survey of your facility, your dedicated customer support specialist will put together a quote customized for your specific needs.

How do I clean the mats or flooring and how often?

Cleaning is a very straightforward process; simply wet mop the entire product with an approved cleaning solution and squeegee dry. One of the many benefits of Dycem mats and flooring is that they can be easily incorporated into your current Standard Operation Procedures (SOPs) and cleaned as part of your regular cleaning and maintenance schedule, provided the right size has been installed to accommodate the amount of traffic.

How do I know if my Dycem product is still working?

As part of our ongoing customer service, we provide a complementary particle collection efficiency test of your Dycem products, completed on an annual basis by your local contamination control specialist. A report will be produced for your records.

My mat looks dirty - is there a problem?

Between cleaning, the floor will look dirty. This is good – if the dirt was not on the floor, it would be in your critical environment. Dycem manufactures both CleanZone and Workzone in a speckled, decorative finish that will help mask the dirt if a reduced visibility option is desired.

What markets do these systems apply to?

Dycem’s commitment to quality, total customer satisfaction and product innovation has earned the company recognition across the globe and today Dycem operates in most markets serving a variety of industries including: Pharmaceutical, Aerospace, Semi-Conductor, Bio Medical, Hospitals, Medical Device, Fibre Optic, Data Centres, Optical, Automotive, Packaging and Food.

Happy Dycem customers

Today, thousands of clean rooms, critical areas and controlled environments are protected by Dycem polymeric contamination control mats and flooring. Our customers include Sony, GlaxoSmithKline, Lilly, Abbott, Johnson and Johnson, Motorola, Roche, IBM, Pfizer, Rolls Royce, Nestle, Bombardier, Intel, Seagate, Nokia, Honda, BMW, Heinz and Texas Instruments.

Like to see how this could work in your facility?

Simply fill in the details below and we’ll get in touch to discuss

how this could work in your facility.

Get in touch