Hello Guest,

The ProfilGate Aqua system is designed to clean and sanitiser footwear and wheels passing over the system, so adding the sanitiser is a critical aspect of this to ensure adequate microbial control. There is the option to add the water and chemical solution manually by using a hose to add the water then adding the correct amount of sanitiser with a jug, evenly over the grates as below.

New concept:

Our customers wanted complete peace of mind that the sanitiser is being replaced regularly each day, so we created the Hygiene Technologies ‘Auto-dose System’, which is essentially a set and forget system that is activated by a timer and doses the correct amount of fluid at the correct dosage rate and frequency each day. The built in overflow drain means that as the new sanitiser solution is introduced into the system, the drain (in the opposite corner) will release a corresponding amount of old solution down the drain so that the sanitiser is kept fresh and active. You can see how the sanitiser disperses through the system here.

How it works

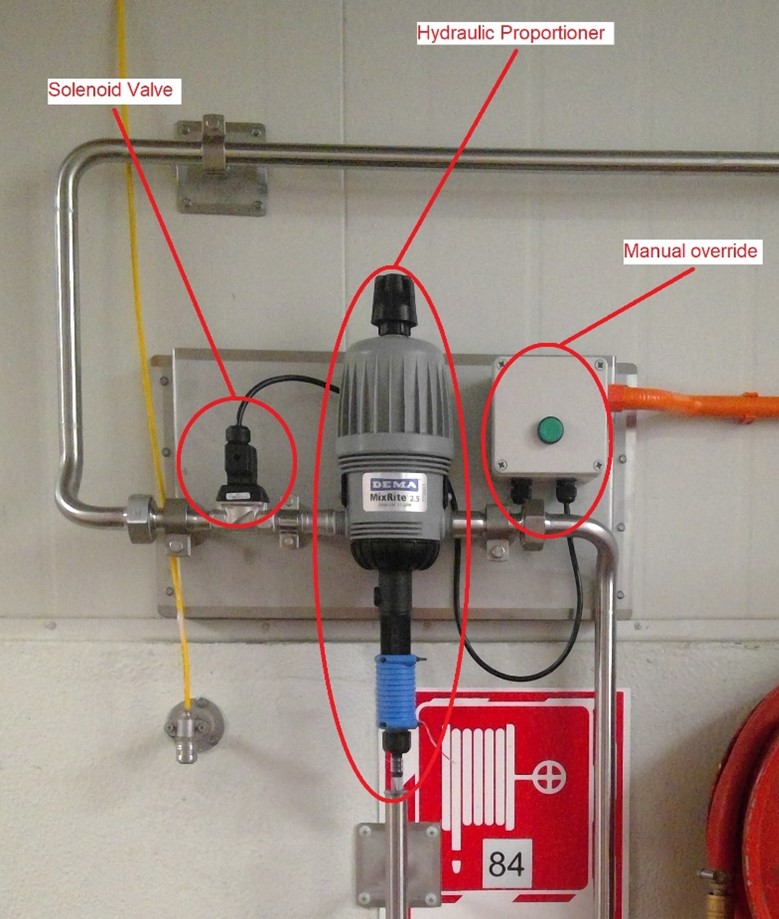

The Auto-dose System’ consists of a hydraulic proportioner that will connect into your water supply and a suction line goes from the chemical to the proportioner, typically from a 20Ltr container nearby. These proportioners accurately dose the sanitiser for going into the ProfilGate tray and compensates for changing flow rates or pressures to keep the chemical dose percentage correct.

The mixed solution is controlled by a solenoid valve which is connected to a timer that is pre-set to run for the correct amount of time required to fill the tray and then switches off. This sequence can be programmed to re-dose many times during a shift if required. There is also the option of a manual over-ride button which allows you to press it once to fill the trays on demand, for instance after you have removed the grates for cleaning and have emptied the trays and rinsed them and now need to refill. See below for examples of a typical set up:

Benefits of the system

This system ensures accurate dosing of the sanitiser every time and gives you the peace of mind that the sanitiser is being replaced before it has lost it’s efficacy, saving reliance on people to remember to replace it when they should. It also gives you the flexibility to dose it whenever required. The system requires very little maintenance and works with varying water pressures. It is pretty much ‘set and forget’ meaning a critical zone is not left to memory of the busy operators.

Chemicals used

Ensure you discuss with a member of our Solutions Team the correct sanitiser product and dilution rate required for this application. We do not recommend chlorine-based sanitisers or ones with a lot of detergency. However, it is important that we know what the product and rate is before we spec the proportioner for the dosing system.

Technical installation details:

The specs of the proportioner will vary depending on the model used as per above point, however all models will have the same connections as below. The other aspects covered below should provide your contractors all the information they require to put this system together, however any questions, please contact us.

– Water supply – 20mm BSPF fitting required, 0.2 – 8bar, 4°C – 40°C (cold water is best for chemicals), minimum flow rate 20Ltrs/hr

– Proportioner outlet – 20mm BSPF fitting required

– Mounting gear – a bracket comes with the proportioner that can be screwed to the wall and the electrical enclosure can also be screwed to the wall with sealing plugs to cap screws. You can make up a

plate to mount the components to if desired, see pictures above for how one of our customers set this up.

– Electrical supply – 240V AC, less than 1A draw

– Timer programming – see the Timer manual and note particularly pages 13-17

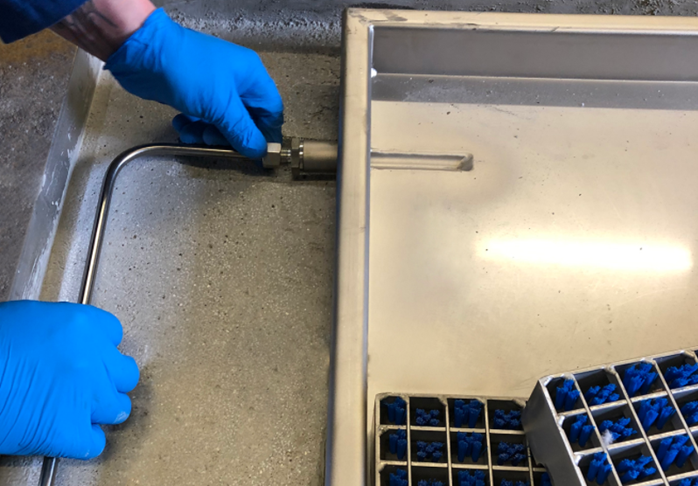

– Tray connection (see pics below) – 15mm BSPM connector required. Further details available for connecting the solution to the tray in the ProfilGate Full installation manual