Hello Guest,

November 2019

Sadly, stories of product recalls due to brush bristles being found in food are not as rare as they should be in NZ, largely due to the operators misunderstanding of correct tool use. Here’s a quick guide to help get a better understanding of the types of brushes available in NZ:

Sadly, stories of product recalls due to brush bristles being found in food are not as rare as they should be in NZ, largely due to the operators misunderstanding of correct tool use. Here’s a quick guide to help get a better understanding of the types of brushes available in NZ:

El cheapo – This class applies to some NZ made brushware, along with the cheaper imported products. They’re

El cheapo – This class applies to some NZ made brushware, along with the cheaper imported products. They’re

made for household use, but find their way into food factories all too often unfortunately.

These brushes have injection moulded bodies that are very low density, which have a lot of air bubbles inside the body meaning they break easily and the staples holding the bristles in are likely to come loose, letting go of the bristles.The staples are often made from mild steel meaning they will quickly rust when they get wet, causing potential contamination and surface staining.

Next we have the bristles, often made from cheap plastic filaments which are not great for use in most food factories. Firstly, they don’t like hot water or strong chemicals so will curl up and deform. Secondly it has a poor memory (like some of us who are getting older) which means the bristles get bent and don’t recover back to their original position after use very well.

The long and short of it is, don’t be tempted to use these products in a food factory – the risks are too great.

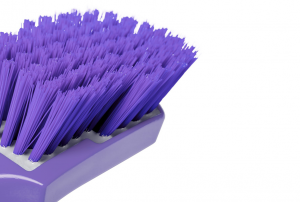

Decent quality gear – The only ranges in this category are all imported from overseas – products like the Fibreclean range.

All the poor features in the El Cheapo ranges have been overcome with this gear. The bodies are high pressure injection moulded so they don’t contain air and provide a solid base for the bristles to be firmly stapled into. The staples are stainless steel to protect against corrosion and the bristles are made of a special grade PBT material providing far superior bend recovery and length of life than Nylon or polypropylene

In addition to this, the tools in these ranges are usually much better designed for ergonomics, making the operators job easier.

Moulded brushes – This option is relatively new, but consists of tightly packed bristle clumps being moulded together to form a bristle unit. These units are then held in a strategic pattern while a brush body is moulded over them to form one brush.

The feedback we have received from our customers on this type of brushware is that the brushes don’t perform very well due to the tightly packed bristle clumps and the brush bodies are thinner leading to more broken brushes. The idea of having no staples is good, but this style is let down by the performance and breakage issues.

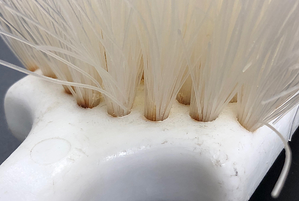

Resin set brushes – This technology is the same as the ‘Decent quality gear’ brushes above, except the brush body has a slight recess where the bristles are stapled into it. In that recess, a resin is floated around the bristles and is then left to set. This has two purposes:

- It’s an extra method of holding the bristles into the brush as well as the staples. This dual retention system gives more peace of mind that the bristle clumps won’t fall out into food process machinery

- It makes the brush easier to clean as every hole that the bristles are stapled into is not a hiding place for soil or moisture now – it’s full of resin

For the ultimate in bristle retention and ease of cleaning in high hygiene areas, choose resin set – it has all the benefits of decent quality brushware as well as the extra assurances mentioned above

Alarm bells – When a bristle is found in product or process equipment, alarm bells ring and often the first reaction is to ring the brush supplier about their brushes. In our experience, the cause of the issue is almost never the brush. That might sound a bit arrogant, so let me explain why this is the case.

You can have the most expensive brush on the planet, but if a bristle is squashed at a pinch point in some equipment, it acts like scissors and can completely sever the bristle filament or crush it so it breaks away with extra bending. The bristle retention system has still worked fine – it is bristle damage that is the issue.

When a bristle retention system fails in a stapled brush, you end up with a ‘V’ shaped bristle filament coming out – not a straight piece of bristle. The most common cause of this is in a soft broom where a single filament is caught at a pinch point and gets pulled out. This loosens the whole bristle bundle making it easier for another filament to escape, loosening it further and then the whole bundle will often fall out. Apart from this situation, most of the bristle filaments we see in product are straight pieces as a result of a filament being damaged to breaking point.

When brushes are NOT the best tool – Where there are ‘pinch point’ situations with food equipment as mentioned above, brushes are usually not the best tool for the job. You might be asking ‘What else can I use then?’ That’s a good question and thankfully the answer is there are better options in a lot of cases.

As an example, often for cleaning a piece of machinery such as a ribbon blender you are better to use a commercial microfibre flat mop system rather than a brush – it removes the bristle damage risk, performs better than a brush and is faster to use.

There are so many different options for different situations that we suggest you contact us to discuss your specific application – our team can work through your situation with you.

What’s the verdict then? To sum it all up, here’s three tips to avoid bristles ending up in your product:

- Check your processing machinery for any pinch points that may potentially snag or cut bristles and note them down (take a photo is a good idea)

- Explore what the best tool and process is for that particular cleaning application with your cleaning tool supplier

- Switch to resin set brushes in your high hygiene areas to get the added benefit of true dual bristle retention

Getting help with your particular situation is easy – simply enter a few details in the form below and one of our team will be straight back in touch with you.

Post by Dayle Senior