Hello Guest,

“Breaking the Cycle” What does it mean and should you do it? “Breaking the cycle” is a commonly used term in the food industry, although somewhat poorly understood. The term originates from the practice of periodically rotating the sanitiser used in a factory’s sanitation program, based on the theory that this will stop micro-organisms building resistance to the most commonly used sanitiser. This in turn would “break the cycle” of re-infection that would occur if the micro’s did in fact build resistance.

This periodic rotation of sanitisers is generally regarded as “best practice” by most of the food safety think-tanks of today, but before making a decision to adopt this practice in your situation, there are four important points you really need to understand, in order to make an informed decision:

1. What are your micro-sampling records telling you?

If you have a robust, pro-active cleaning program in place, and operate a robust, random, micro sampling plan to monitor its effectiveness, and your track record of micro samples over twelve months is consistently good, then there is very little point in you rotating your sanitiser. This is especially true if, for any micro “spikes” that occurred, you thoroughly investigated the cause and could put it down to a tangible cause that was out of the ordinary, and therefore not related to the performance of your sanitiser – e.g. – “New cleaner on the team did not scrub the inside of the mixer effectively” or “Pipe in the ceiling was found to be leaking and this dripped on to process equipment after cleaning was finished”.

2. What is the root cause of a micro spike?

Unfortunately, a common knee-jerk reaction to a micro spike is to immediately blame the sanitiser and switch to using a different one, instead of properly investigating the factors that contributed to it. This is akin to using a different coloured Band-Aid to treat a broken arm – the root cause is still present and will continue causing problems until fixed. There are any number of reasons for a micro spike to occur that are not related to the efficacy of the sanitiser. Remember, a sanitiser is designed to sanitise pre-cleaned surfaces after a specified dwell time on the surface. If your sanitiser is applied to a dirty surface, is not applied properly, or is rinsed off too quickly, which results in a micro spike, then it is your process that needs fixing, not your sanitiser.

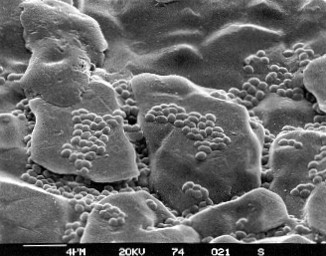

3. A word about bomb shelters

As with most living things, micro-organisms have a strong interest in self-preservation. One of the well-known ways in which they protect themselves is to build and live in biofilms, which are basically like little bomb shelters, which shield them from the biocidal action of most commonly used sanitisers. As a rule of thumb, most vegetative cells are killed with ease by the commonly used sanitisers, when they are by themselves “out in the open” without the protection of a biofilm. However, and this is a very pertinent point, most commonly used biocidal agents, including those that claim to have “no known incidences of resistance”, are efficacy tested according to the common laboratory “suspension test”. This is where a known amount of bacteria is added to a test tube, and then dosed with a certain amount of biocide. The results are then calculated after a certain time period to measure efficacy. The fact is (disturbingly) that this style of test, where bacteria are floating freely in liquid, does not, in the majority of applications, mirror real life conditions of bacterial behaviour in a food factory. In reality, the majority of microorganisms are sessile (permanently attached to a surface) – often with the aid of a biofilm matrix. So, if your micro results start trending in the wrong direction, and you can’t identify any tangible reason why, you are best to put your efforts into identifying and removing any biofilms from your process, before going to the step of changing your sanitiser. The reason is because, if a biofilm is allowed to remain on a surface, more than likely, a different sanitiser will also be ineffective.

As with most living things, micro-organisms have a strong interest in self-preservation. One of the well-known ways in which they protect themselves is to build and live in biofilms, which are basically like little bomb shelters, which shield them from the biocidal action of most commonly used sanitisers. As a rule of thumb, most vegetative cells are killed with ease by the commonly used sanitisers, when they are by themselves “out in the open” without the protection of a biofilm. However, and this is a very pertinent point, most commonly used biocidal agents, including those that claim to have “no known incidences of resistance”, are efficacy tested according to the common laboratory “suspension test”. This is where a known amount of bacteria is added to a test tube, and then dosed with a certain amount of biocide. The results are then calculated after a certain time period to measure efficacy. The fact is (disturbingly) that this style of test, where bacteria are floating freely in liquid, does not, in the majority of applications, mirror real life conditions of bacterial behaviour in a food factory. In reality, the majority of microorganisms are sessile (permanently attached to a surface) – often with the aid of a biofilm matrix. So, if your micro results start trending in the wrong direction, and you can’t identify any tangible reason why, you are best to put your efforts into identifying and removing any biofilms from your process, before going to the step of changing your sanitiser. The reason is because, if a biofilm is allowed to remain on a surface, more than likely, a different sanitiser will also be ineffective.

4. The all-important “mode of action

If, after going through the above steps, it appears that the micro population in your factory is actually starting to build resistance to the sanitiser you use, then you should look at trying a different type of sanitiser. The important thing to remember when at this stage, is that the active ingredient of the new sanitiser should have a different “mode” or “mechanism” of action than the one you have formerly been using. This will give it the best chance to be successful against the new behaviour the organism has learnt through continual exposure to the previous sanitiser. To explain it in another way, if poisoning the bacteria’s coffee is no longer effective, try hitting it over the head with an axe! We have come across a number of incidences where the customer thought that by changing to a different brand of the same type of sanitiser, they would be successfully “breaking the cycle”. Not surprisingly, this did not achieve the desired result, because the mode of action was no different.

If you would like further help or information on this subject, or advice on the different types of sanitisers, or on how best to identify and remove biofilms from your process, please enter your details here and we’ll be right in touch with you:

Posted by Glen Senior